The 4 façade experts join forces to create Weclad

The aim is to promote technical, industrial and commercial synergies, to better meet the challenges of the European façade market.

In this key segment of architecture and building energy performance, Weclad is positioning itself as the leader in eco-responsible architectural facades in Europe.

The alliance of 4 benchmark façade manufacturers

In both new-build and renovation projects, the 4 façade manufacturers have recognised expertise in their respective markets in terms of design and custom off-site construction. By joining forces in the Weclad alliance, they are combining their technical, industrial and commercial capabilities to guarantee their customers the best possible offer in terms of quality, design and durability.

The Weclad alliance comprises Kyotec, Rinaldi, De Groot & Visser and Techniwood.

- Kyotec is the European façade specialist in complex, technical and multi-material building envelopes for large-scale projects.

- Rinaldi is the definitive French cladding company developing bespoke prefabricated solutions.

- De Groot & Visser is the leading Dutch company focusing on cladding renovation and low-carbon façades.

- Techniwood specialises in the design and manufacture of wooden off-site façades, and the originator of Panobloc® wood technology.

Integrated technical teams

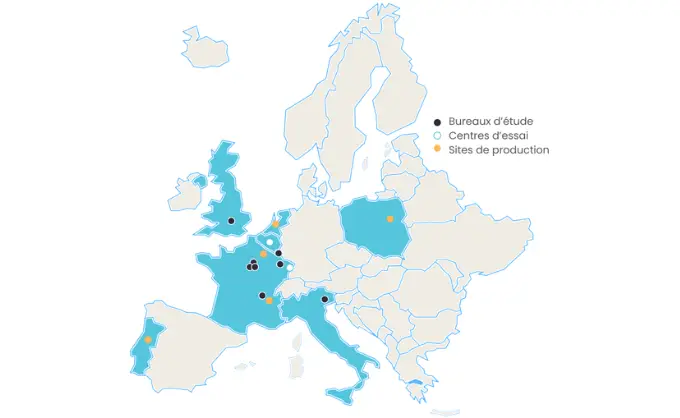

Weclad represents the largest international network of integrated façade design experts, spread across Europe in six design offices. The alliance’s knowledge of the specific regulatory requirements of each country, the sharing of best practice from its portfolio of European projects, and its experience of cross-cultural collaboration combine to provide a compelling offer. Design teams are involved right from the commercial phases and liaise closely with the production teams from the outset to ensure total visibility and control of each project.

Pooling pioneering sustainable solutions

The patented solutions developed by each business within Weclad are also shared across the alliance. These include the Panobloc® façade panels (made from renewable materials), the Evost® HVAC system (energy-efficient and modular), and Kyofix (an invisible fixing system for stone cladding).

As part of the Léon Grosse Group's decarbonisation strategy, the Weclad businesses automatically offer a low-carbon alternative in the commercial phase and share the same overall timetable for reducing greenhouse gas emissions by 15% by 2025.

A shared production capacity unique in Europe

Weclad's five production plants (in France, Poland, Portugal and the Netherlands) give the alliance the capacity to support projects of all types in Europe.

This multi-site production capability means that the technological options available for customised design can be increased tenfold, while providing more flexibility in terms of production and logistics.

“The Weclad alliance consolidates the extensive specialist expertise of leading European players in the architectural façades sector, providing a compelling offer of high-performance, tailor-made solutions for our customers’ requirements throughout Europe.”

Bruno Moyne Managing Director, Weclad alliance

Weclad in figures

0

employees in eight countries: United Kingdom, France, Belgium, Luxembourg, Netherlands, Italy, Portugal and Poland

0

design offices, two test centres and five production sites

0

million turnover

Alliance member projects

Conception et installation des façades du Skypark business center - Aéroport de Luxembourg

Conception et installation des façades d'un projet collé à l’aéroport de Luxembourg, avec de nouvelles fonctions :

- restaurants,

- commerces,

- bureaux,

- hôtel,

- espaces de coworking,

- parking souterrain,

- espaces verts en terrasses.

Press department

Press relations manager

+33 6 99 13 82 16

l.perhaut@weclad.com